| Sign In | Join Free | My ecer.com.ru |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My ecer.com.ru |

|

Place of Origin : Jiangsu

Brand Name : Golden

Certification : ISO9001,UL,CE

Model Number : Customized

MOQ : 1 pc

Price : 30usd to 2500usd

Packaging Details : Box Or Wooden Package

Delivery Time : 8-25 working days

Payment Terms : L/C, T/T, Paypal

Supply Ability : 3000 tons/month

Material : Alloy Steel 34CrNiMo6

Weight : 50Kg-5000Kg

Machining : Rough Machining Or Finish Maching

Jewelry type : Rings

Jewelry main material : Stainless Steel

Rings type : Engagement Bands or Rings

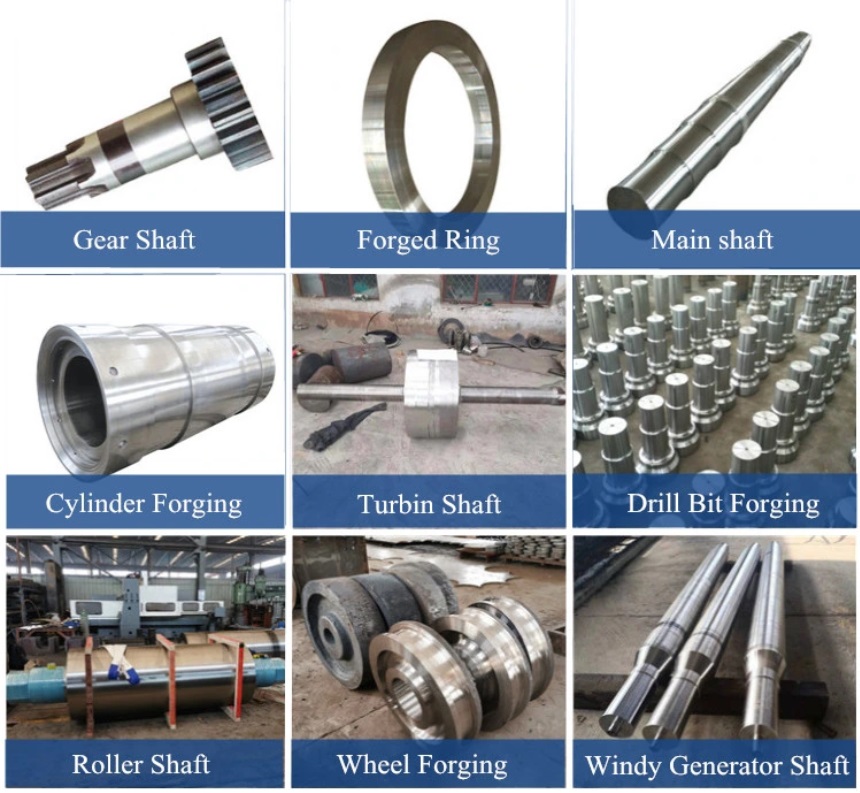

34CrNiMo6 Rough Machining Hot Rolled Forging Steel Retaining Rings

Ring Forging Usage

All kinds of cars,machinery,home appliance,electronic products,electric appliance,stationery,computers,power switches,miniature switcher,architecture,commodity and A/V equipment,hardware and plastic molds,sports equipment and gifts,and more.

Ring Forging Chemical Element:

| C% | 0.30~0.38 | Si% | ≤0.4 | Mn% | 0.5~0.8 | P% | ≤0.035 |

| S% | ≤0.035 | Cr% | 1.3~1.7 | Mo% | 0.15~0.3 | Ni% | 1.3~1.7 |

Ring Forging process:

The forgings manufacturing and inspecting process are showed in the following picture :

Certfiticates List:

| Certificates list of Jiangyin Golden | ||

| ISO9001:2008 | ISO14001:2004 | PED Certificate |

The main manufacturing equipments

| Name&Description | Capacity | Quantity |

| 3600Thydraulic press | Max. single forging in 18T | 1 |

| 2000T hydraulic press | Max. single forging in 9T | 2 |

| 800 hydraulic press | Max. single forging in 5T | 1 |

| 6T electrical hydraulic hammer | Max.single forging in 5T | 1 |

| 3T electrical hydraulic hammer | Max.single forging in3T | 1 |

| Air hammer | Max.single forging from250kg to 1000kg | 7 |

| Forging operation machine | Max.singe forging from20T-5T | 7 |

| Heat treatment Furance | Max.8000*5000*1500mm | 11 |

| CNC driling machine | Max.5000mm | 2 |

| Vertical lathe | From 1600 to 5000mm | 60 |

| Horizontal lathe | Max.5000mm | 70 |

| Band sawing machine | 260-1300mm | 36 |

Test instruments:

|

Item | Name |

Model |

Precision |

Quantity |

Calibration cycle |

Remarks |

| 1 |

UT fault detector | CUD2080 | 4 |

1year | ||

| 2 |

UT fault detector | PXUT-U1 | 1 |

1year | ||

| 3 |

UT fault detector | PXUT-U350+ | 1 | 1year | ||

| 4 |

Yoke flaw detector | DA-400S | 1 | 1year | ||

| 5 |

UT fault detector | USM 35X | 2 | 1year | ||

| 6 |

UT fault detector | USN 60 | 1 | 1year | ||

| 7 |

Reading directly spectrographer | SPECTROTEST TXCO2 | B Class | 3 | 1year | |

| 8 | Reading directly spectrographer | GS 1000 | A Class | 1 | 1year | |

| 9 |

HB tester | HB-3000B | ±2.5% | 1 | 1year | |

| 10 |

Leeb hardness tester | TH140 | ±12HLD | 4 | 1year | |

| 11 |

Leeb hardness tester | EQUOTIP3 | ±12HLD | 1 | 1year | |

| 12 |

Digisplay Rockwell hardness tester | HRS-150 | ±1.5HRC | 1 | 1year | |

| 13 |

Portable HB tester | ±3.0% | 1 | 1year | ||

| 14 | Automatic end quenching test machine | WDZ-02 | 1 | |||

| 15 |

Metallurgical Micaroscopy | XJP-6A | 1 | 1year | ||

| 16 |

Chemical analysis equipment | 1Set | 1year |

|

|

|

34CrNiMo6 Rough Machining Hot Rolled Forged Steel Ring Large Metal Rings Images |